Avoid investing unnecessarily on overpriced printed t-shirts, you may be able to print your own. Knowing how to print your own t-shirts will save you money and give you the freedom to produce whatever design you desire.

atlantagraphicsandprinting.com gathered information on how you can print t-shirts at home and the different methods you can use.

T-shirt Printing

With so many different ways to print on t-shirts, how do you know which method to choose? Consider the following printing methods, their advantages, and disadvantages:

1. Sublimation Printing

Sublimation printing is unquestionably the best professional way to print on synthetic (polyester) material. However, this printing method does not work on other kinds of fabric with all-natural fibers, like cotton or wool. This costly method uses heat to turn dye (ink) into a gas that immediately bonds with the fabric.

Sublimation printing creates soft, permanent designs on synthetic materials like polyester. Because of the unique way the dye sticks to the fabric, it leaves the garment feeling breathable instead of leaving what feels like a thick coating on the material. Sublimation designs won’t crack or peel.

The disadvantage of this technique is its cost. You need a lot of commercial equipment for this process, making it more cost-effective for a large business than for home use or a small business. Also, you cannot use the sublimation method on cotton t-shirts.

While this printing method can produce some incredible-looking products, it will severely limit you to a narrow range of fabrics.

2. Screen Printing

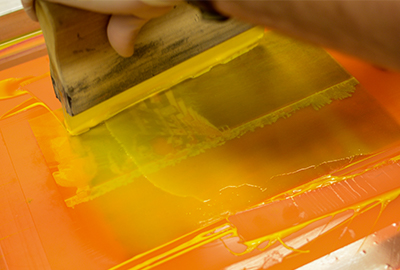

Screen printing is among the highest-quality t-shirt printing currently available, leaving space for creativity and artistry. It is also one of the oldest printing methods.

In this method, you begin by making a negative of the design you want on your screen. You then apply plastisol ink over the screen and press the screen onto the t-shirt. This process forces ink through the negative space on the design and leaves an image on the shirt.

Screen printing is a popular choice for high-quality, professional t-shirt designers and for home artists. First, screen printing creates vibrant and durable designs. These have a raised and slightly stiff feel on top of the fabric, but the ink soaks into the material, making it more lasting.

3. Airbrushing

Airbrushing is not the best t-shirt design choice for a big commercial operation, but it is popular among artists and small-scale printing and craft businesses. This t-shirt design method facilitates complex and artistic designs. This method can also be used as a substitute for screen printing by airbrushing over stencils, one color layer at a time.

Advantages of airbrushing include its versatility and (once you gain some experience) precision. Another airbrushing “plus” is that it does not cost much to get started.

Note: You can also mix and use several different types of paints and dyes.

The disadvantage to airbrushing is the time it takes to produce a finished product. While this method allows greater artistic expression, it may take hours to complete one shirt. It may also be challenging to replicate shirts when you want or require more than one of the same design.

4. Stenciling

Stenciling is the simplest method you can use on t-shirts at home. You can cut out a stencil, then apply dye over the stencil, creating an image or design on the shirt.

Professionals often used more advanced forms of stenciling in methods like screen printing. However, you can replicate this at home with simple tools if you just want to make a few t-shirts for your friends or family.

The advantages of stenciling include making designs as complex or simple as you need them to be, and no fancy technology or expensive equipment is required.

The disadvantages are that this method works better for personal use and will not give you the professional edge you will need to produce and sell shirts.

5. Direct To Garment (DTG)

Direct To Garment (DTG) printing or direct to fabric printing (DTF) is a process that does exactly what it says; a DTG or DTF printer applies a thin layer of ink directly onto the t-shirt!

This permits you to create t-shirts with any design that you could print onto paper. You can use multiple colors, create more complex graphics, or even use photos. In this method, ink soaks into the shirt’s fabric, leaving the design feeling soft to the touch instead of leaving you with a hardened layer of ink on the fabric. With this method, you can quickly print one design after another without any complex processes or setup.

The disadvantages of DTG include the initial setup cost, which can range from $10,000 to $500,000. If your intent is to launch a t-shirt business, this method’s start-up cost is likely worth it.

Custom Printed T-shirts

In this article, you discovered several T-shirt printing methods and tips you can use to produce high-quality T-shirts from the comfort of your home.

Printing T-shirts at home allows you the freedom to determine the design, color use, and overall shirt quality, whether printing them for family gatherings, reunions, company outings, milestone celebrations, or whatever the purpose.

When ordering printed T-shirts from a 3rd party, you risk getting poor quality shirts, incorrect ink colors, poorly designed graphics, and an insanely overpriced final product.

Sources:

scholarworks.lib.csusb.edu/cgi/viewcontent.cgi?article=1032&context=cap-curr

makingcenter.parsons.edu/wp-content/uploads/2016/09/DyeSub_2021.pdf

sites.psu.edu/wp-content/uploads/sites/13153/2013/11/Addleman_Demirci_Notor_Instruction_Set.pdf